Understanding Grid Injection Skids and Online Chromatographs for Compressed Bio Gas (CBG)

- sofconblogadmin

- Posted on

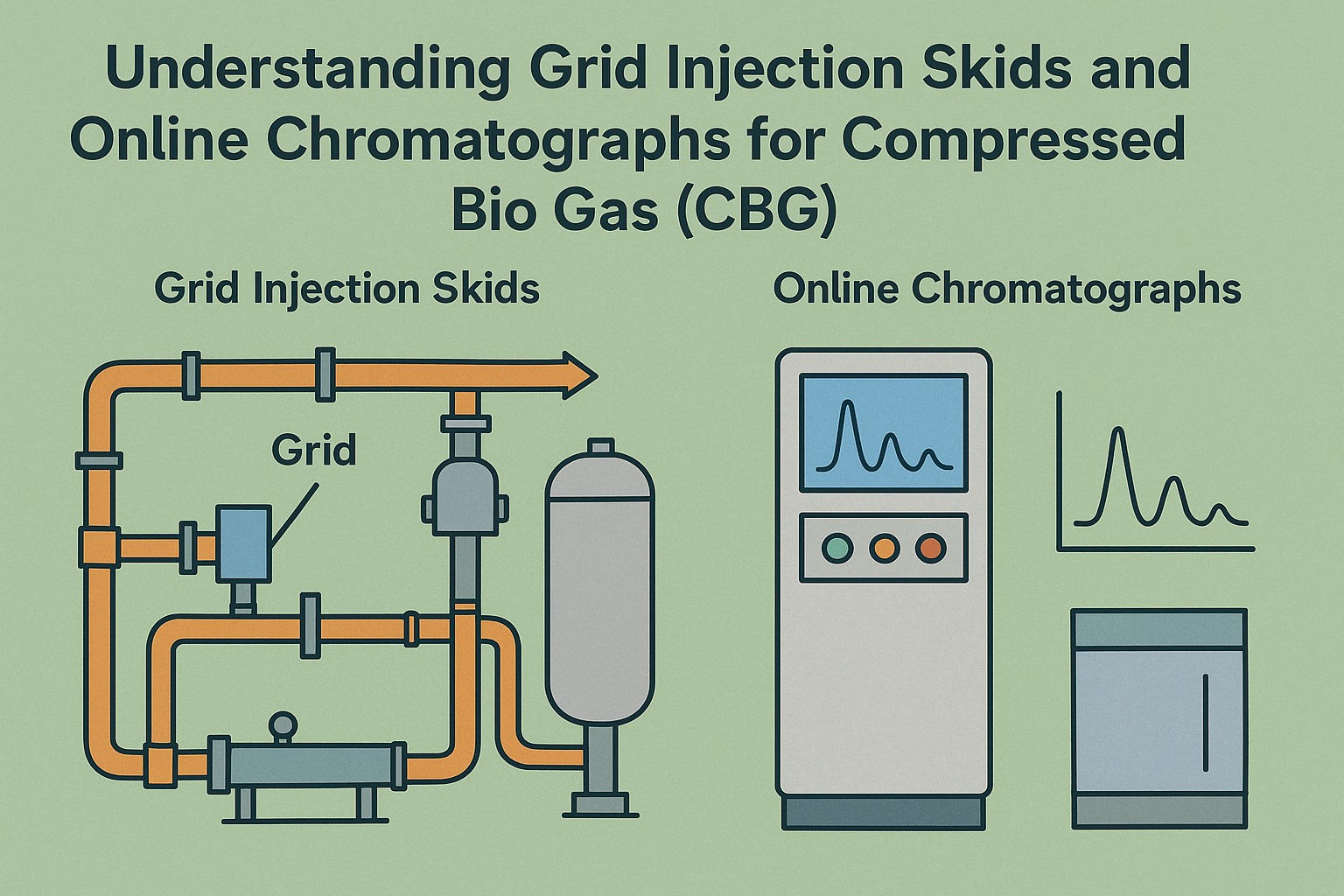

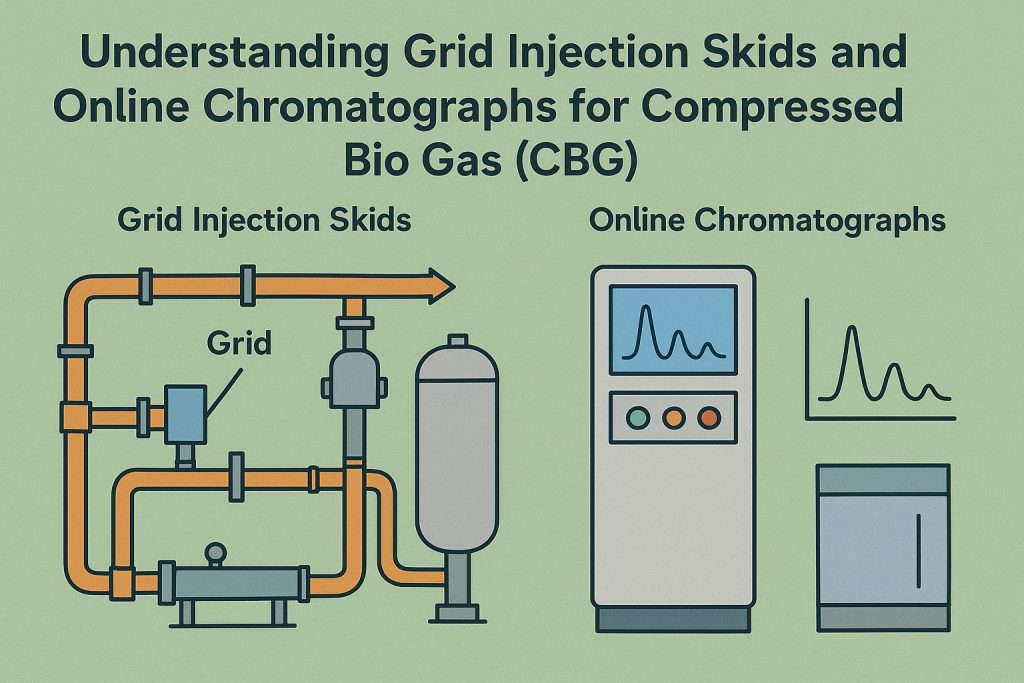

The demand for sustainable energy solutions is on the rise, and Compressed Bio Gas (CBG) is emerging as a reliable, eco-friendly alternative to conventional fossil fuels. To ensure the seamless supply of CBG to the national gas grid, specialized equipment like Grid Injection Skids and Online CBG Chromatographs are used. These systems must comply with industry standards such as GAIL’s specifications and City Gas Distribution (CGD) norms for safety, quality, and performance.

What is a Grid Injection Skid for CBG?

A Grid Injection Skid is a compact, integrated system designed to inject CBG into the natural gas grid after proper conditioning, metering, and quality checks. It acts as the interface between the CBG production plant and the transmission/distribution pipeline.

Grid Injection Skid for CBG as per GAIL’s Standard

GAIL (Gas Authority of India Limited) specifies detailed guidelines for CBG injection to ensure compatibility with the existing gas grid.

A Grid Injection Skid for CBG as per GAIL’s standard includes:

- Gas Quality Analysis: To confirm the CBG meets the required methane content and impurity limits.

- Pressure Regulation: Ensures safe delivery pressure to the grid.

- Flow Measurement: Accurate metering as per prescribed accuracy classes.

- Safety Controls: Automated shutdown in case of deviations in quality or pressure.

- Compliance with IS 16087:2016: Ensuring gas quality parameters align with national standards.

Grid Injection Skid for CBG as per CGD Standard

City Gas Distribution (CGD) companies have their own guidelines, aligned with safety and operational efficiency.

A Grid Injection Skid for CBG as per CGD standard typically includes:

- Customized Flow Control: Designed to match the specific distribution network’s requirements.

- Odorization Units: To comply with safety norms for leak detection.

- Automated Monitoring: Integration with SCADA systems for real-time performance tracking.

- Local Compliance Checks: Adhering to state and city-specific energy regulations.

Role of Online Compressed Bio Gas (CBG) Chromatograph

Gas quality is critical when injecting CBG into the grid. An Online Compressed Bio Gas or CBG chromatograph as per GAIL’s standard IS 16087:2016 ensures continuous, real-time analysis of the gas composition.

Key Features:

- Methane Percentage Measurement: To verify calorific value.

- Detection of Impurities: Such as carbon dioxide, hydrogen sulfide, and moisture content.

- Compliance with IS 16087:2016: National standards for gas quality testing.

- Automated Data Logging: For operational records and compliance reporting.

Why Standards Like GAIL’s and CGD’s are Important

Following these standards ensures:

- Safety: Preventing operational hazards in pipelines.

- Quality Assurance: Maintaining consistent fuel quality for end-users.

- Interoperability: Smooth integration with existing infrastructure.

- Regulatory Compliance: Avoiding penalties and operational delays.

Conclusion

The adoption of Grid Injection Skids for CBG and Online CBG Chromatographs is essential for scaling India’s green energy ecosystem. Whether built to GAIL’s standard or CGD’s standard, these systems ensure that every cubic meter of CBG delivered to the grid meets the highest benchmarks of quality, safety, and efficiency.

With growing investments in bio-energy projects, implementing equipment that aligns with IS 16087:2016 and other national norms is no longer optional—it’s a necessity for a sustainable future.